Excavator Cutting Edge

Excavator Cutting Edge Quanzhou Peers Construction Machinery Parts Co., Ltd is a large-scale Excavator Cutting Edge manufacturer and supplier in China. We have been specialized in heavy duty equipment parts for many years. Our products have a good price advantage and cover most of the European, Amer......

Send Inquiry

Product Description

Excavator Cutting Edge

Quanzhou Peers Construction Machinery Parts Co., Ltd is a large-scale Excavator Cutting Edge manufacturer and supplier in China. We have been specialized in heavy duty equipment parts for many years. Our products have a good price advantage and cover most of the European, American, The Middle East, Southeast Asia, and Africa markets. We look forward to becoming your long-term partner in China.

Blade and end Bits are made from Material:35MNB, 16MN or Carbon Steel.Hardness heat treatment: Carbon HRC280-320HB, Boron HRC440-520HB, Yielding Point: Carbon 600Re-N/mm2 , Boron 1440N/mm2, Tensile Strength; 1030 RM-N/mm2,1674 RM-N/mm2.these will ensure the Excavator Cutting Edge more durable.

We offer a wide range of Excavator Cutting Edge to suit most common makes and models of Excavator and Loader on the market today. Which are applies to bulldozers, Loaders motor graders and Tractor from Komatsu, Caterpillar, Hitachi, Sumitomo, Kobelco, Kato and Daewoo.....

◆ 1.Some part of Excavator Cutting Edge as below

Model of cutting EdgeApplicable to Bulldozer Model of End Bit Applicable to BulldozerModels of Cutting Edge Applicable to Motor Grader

Caterpillar

Parts No.Cutting EdgeParts No.End BitParts No.

4T6230D3C6Y5839D3C4T223

4T2972D4E6Y5840D3C4T2244

4T2982D4E5J6941D4D4T2236

8J1489D4D5J6942D4D5D9553

8J1490D4D4T3051D4E5D9554

6J1406D5D4T3052D4E5D9556

4T2985D6H3G8297/6J0895D6D5D9557

4T2948/5J6888D7G3G8298/6J0896D6D5D9558

9W8874D6H5D9559

9W8875D6H5D9561

3G8315/5J8767D7G5D9562

3G8316/5J8768D7G7D1158

8E4193D8N7D1577

8E4194D8N7D4508

KOMATSULoader

Parts No.Cutting EdgeParts No.End BitParts no.Weld-on Edge

101-71-12370D2012F-929-2170D201359395226

12F-70-31251D3111G71-31170D314T2918910

12F-70-31261D31144-70-11170D50/D651U1464930

12F-70-31281D31144-70-11180D50/D651U0292936

13F-70-51130D50150-70-21346D858V1825936

13F-Z27-1510D50150-70-21356D851V3915944

144-70-11131D65175-71-22272D1551V3917950

144-871-5130D65175-71-22282D1558K8162950

144-920-1120D65175-70-21126D1553G6395966

14Y-71-11210D65175-70-21136D1557I3015972

154-70-11314D8517M-71-21930D2759R4672428/416

154-72-11151D8517M-71-21940D2751052345938F

175-70-26310D155195-71-11173D3751406823970F

17M-71-21550D275195-71-11183D3751U0761980C

195-71-11654D275195-71-61930D3756Y2107980G

198-71-11181D375195-71-61940D3759U3748988F

198-71-31250D4754168151210WA100

198-71-31260D47511045808L120

◆ 2.Features of Excavator Cutting Edge

1. Good Performance

We use boron or carbon steel to produce our Excavator Cutting Edge, both of which are durable and wear-resistant metals.

2. 10 Year’s Popularity

We are one of the first group of manufacturers that developed this kind of bulldozer undercarriage parts in China. Our Excavator Cutting Edge have been on the market for more than 10 years and are widely popular.

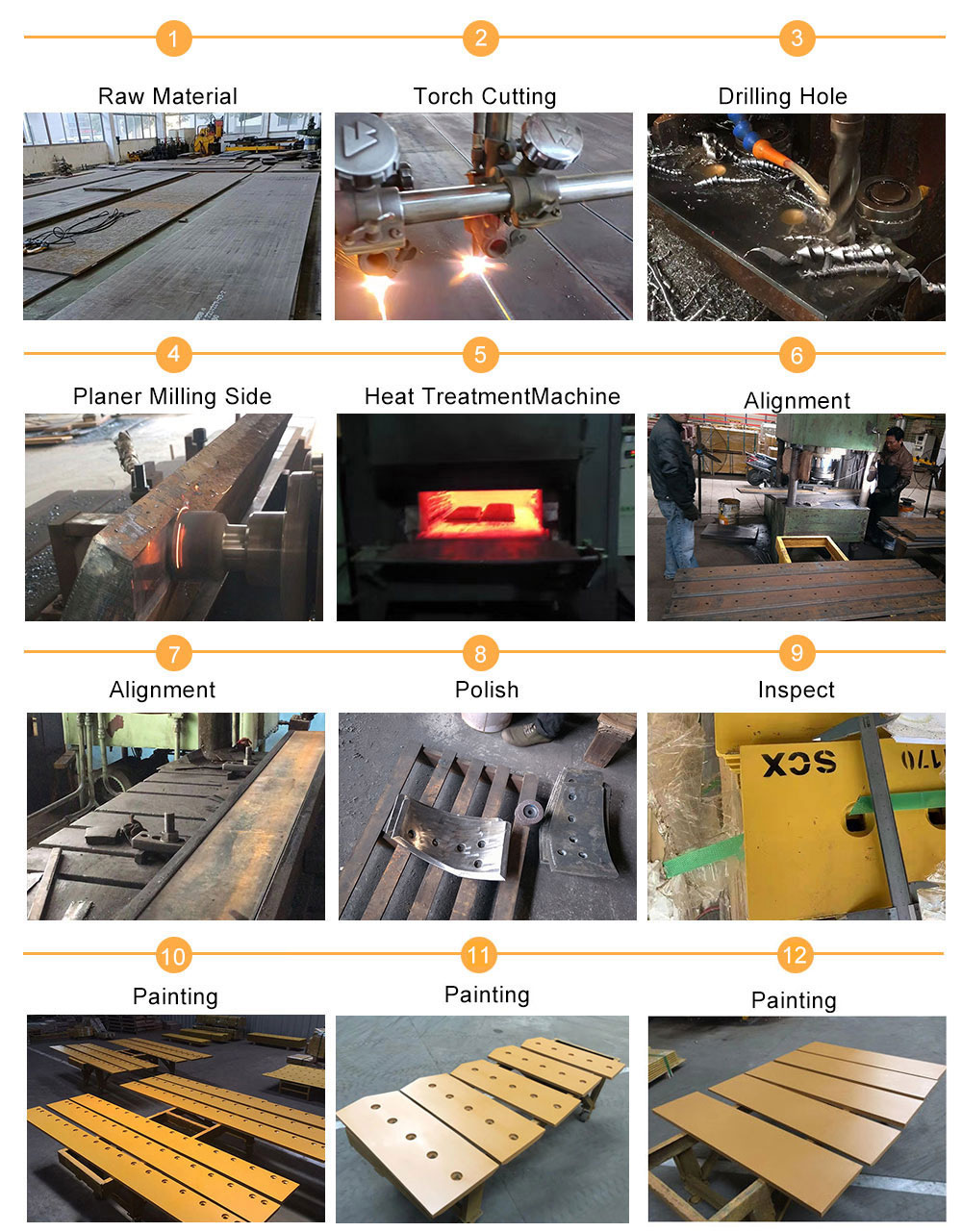

3. Concise Manufacturing Process

Normally Excavator Cutting Edge takes a number of time-consuming steps to manufacture these undercarriage parts, but with our advanced equipment, we have condensed it into a simple three-step process.

4. Advanced Processing Technologies

Excavator Cutting Edge processing technologies include gas cutting and blanking, one-time moulding, heat treatment, and paint spraying.